05-12/2025

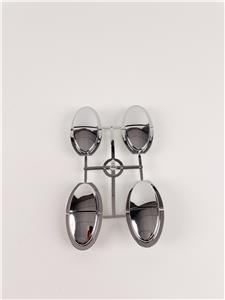

vacuum formed product protection tray for Laboratory reagent tray.

Function: Designed with 4 snap locks, this vacuum-formed tray is intended to stack products and prevent fluid leakage. Additionally, it is capable of withstanding low temperatures down to -80°C.

plastic vacuum forming plastic mold for packaging.

Custom plastic packaging manufacturing. Custom vacuum forming mold, vacuum mold

custom plastic packaging for food, cosmetic makeup, electronic devices, medical supplies, etc.