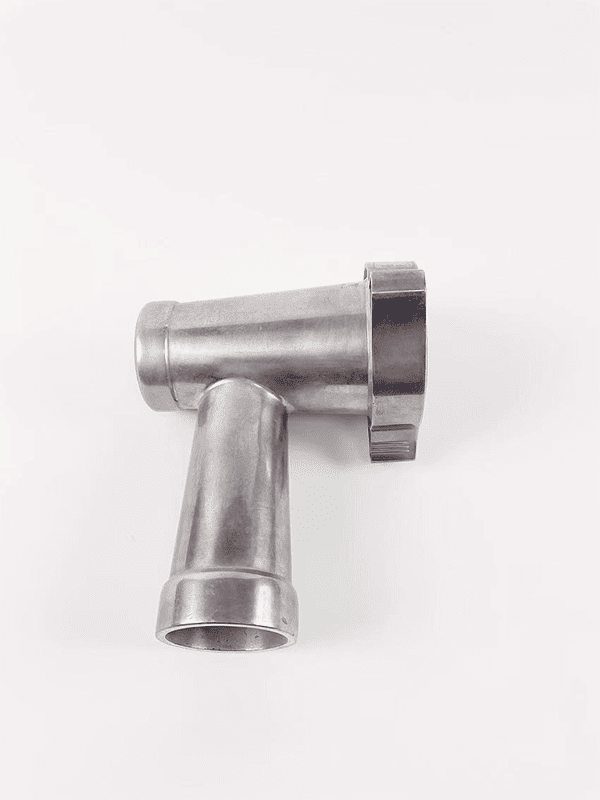

Product Name: Precision Zinc-Aluminum Die Casting Components

Description: Engineered for excellence, our high-precision zinc-aluminum die casting parts deliver

superior dimensional accuracy, intricate detail, and exceptional surface finishes. Utilizing advanced

die casting technology, we produce robust components ideal for demanding applications across diverse

industries.

Key Applications:

*Automotive: Engine components, transmission parts, housings, brackets, sensors.

*Home Appliances: Structural frames, motor housings, handles, connectors, decorative trim.

*Electronics: Heat sinks, enclosures, connectors, shielding components, brackets.

*Furniture: High-strength fittings, hinges, decorative hardware, structural supports.

*Industrial Equipment: Gears, levers, pump components, valve bodies, machine parts.

*(Add other relevant industries if applicable, e.g., Lighting, Medical Devices, Telecommunications)

Core Manufacturing Process: High-Pressure Die Casting (HPDC)

Mold Specifications:

*Standard: HASCO (Global standard for mold components ensuring quality and interchangeability).

*Steel Grade: Premium 1.2344 (DIN Standard) / H13 Equivalent (Hot-work tool steel offering outstanding

thermal fatigue resistance and toughness).

*Cavity Configuration: Single Cavity (Optimized for complex geometries, tight tolerances, and high-volumproduction runs).

*Surface Treatments: Comprehensive options available including Painting, Powder Coating, Polishing,

Electrophoresis, Electroplating, and more to meet functional and aesthetic requirements.

*Guaranteed Mold Life: 1,000,000+ cycles (Demonstrating exceptional durability and long-term

cost-effectiveness).

Product Specifications:

*Material: High-Quality Aluminum Alloys (Specify common alloys like ADC12, A380, etc., if possible, otherwise keep as is).

*Typical Cycle Time: ~60 seconds (Ensuring efficient high-volume production capability).

*Lead Time: Standard tooling and production lead time: Approximately 4 weeks (Subject to project

complexity and order volume).

Value Proposition:

*Unmatched Precision: Capable of producing complex shapes with tight dimensional tolerances.

*Superior Surface Quality: Wide range of finishing options for both function and appearance.

*High Volume Efficiency: Optimized cycle time and million+ shot mold life enable cost-effective

mass production.

*Material Versatility: Expertise in zinc-aluminum alloys for optimal strength-to-weight ratio and

performance.

*Reliable Supply: Consistent quality and dependable 4-week lead time.

*Durability: Components built to last, backed by high-performance tooling.

Ideal For: Engineers and procurement specialists seeking reliable, high-precision, cost-effective

metal components for demanding applications requiring complex geometries, excellent finishes,

and consistent quality in high volumes.

Ready to discuss your precision die casting requirements? [Contact Us Today] or [Request a Quote].

Contact: Norah Huang

norah@highwingmold.com