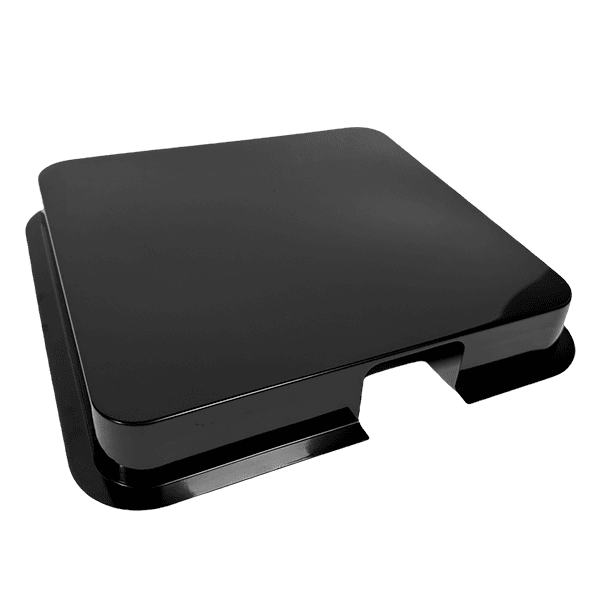

Vacuum Formed Condensation Tray Covers – Customized Vacuum Formed Plastic Packaging Solutions

As industries such as food, cosmetics, electronics, and medical devices continue to improve the functionality and aesthetics of packaging products, vacuum formed condensation tray lids (Vacuum Formed Condensation Tray Lid) came into being. This product is made of PET material and produced through our professional vacuum forming process, providing customers with customized packaging solutions that are moisture-proof, breathable, lightweight in structure and with clear details.

Precision vacuum mold

• Mold standards: designed and manufactured strictly in accordance with HASCO international standards;

• Mold material: Selected 718H high-quality mold steel, with mirror polished surface to ensure that the surface of the molded parts is smooth and traceless;

• Multi-cavity design: 4–8 cavities are connected in parallel to increase production capacity and reduce unit costs;

• Long life: mold life ≥100,000 molding cycles.

Efficient vacuum forming plastic process

• Material selection: food grade/medical grade PET sheet, thickness adjustable from 0.3–1.5 mm;

• Molding cycle: only 30 seconds per cycle, achieving fast turnaround;

• Detail restoration: 90–95 kPa vacuum adsorption, accurately rendering the mold texture and undercut structure;

• Dimensional stability: Reasonable demoulding slope and silicone-assisted design ensure smooth demoulding and high product yield.

Customized services

• Any size and shape: Trays and lids can be flexibly designed according to customer product size, shape and arrangement requirements;

• Rapid prototyping: complete mold design, manufacturing and small batch trial production within 2 weeks;

• Post-processing: Provide one-stop services such as automated CNC trimming, spotlight welding, silk screen printing or inkjet coding;

• Fully compatible: works seamlessly with vacuum formed plastic trays and other packaging components.

Vacuum forming process

Plate preheating: uniformly heat the PET plate to 140–180 ℃;

Mold adsorption: The heated plate is placed on the vacuum table, and the vacuum pump (90–95 kPa) is turned on to adhere closely to the mold;

Cooling and shaping: Turn off the heating, and after cooling for 30-120 seconds, the plastic will solidify and maintain its shape;

Demold removal: Use reasonable slope and mechanical ejection mechanism to easily take out the finished product;

Trimming and packaging: CNC edge trimming machine or die cutting machine trims the edges, and then inspects and packages them after completion.

Application areas

• Food packaging: fresh-keeping tray cover, moisture-proof and condensation-proof design, suitable for fruits, vegetables, and fresh food cold chain;

• Cosmetics: skin care products, facial mask tray cover, waterproof and anti-fog, highlighting product texture;

• Electronic components: wiring harness, PCB, sensor tray, moisture-proof and dust-proof, easy for automatic loading;

• Medical devices: syringes, testing reagent trays, comply with GMP/ISO health level requirements.

Why choose us?

Professional experience: More than ten years of experience in R&D and manufacturing of vacuum forming molds, with industry reputation guaranteed;

One-stop service: from 3D design, mold flow analysis to mold manufacturing, molding production and post-processing, quickly respond to customer needs;

Cost advantage: multi-cavity mold and efficient molding process reduce unit cost;

Quality assurance: Strictly implement the ISO9001 quality management system, and the first sample and full inspection report are fully traceable;

Global delivery: exported to Europe, America, Southeast Asia and other markets, supporting a variety of trade terms and logistics methods.

Contact us

Vacuum Formed Condensation Tray Lid expert, looking forward to customizing your exclusive "Vacuum Formed Condensation Tray Lid" solution!

Contact: Robert Gao

Email: robertgao@highwingmold.com

Phone/WeChat: +8613923770845

Official website: www.hwitcnc.com