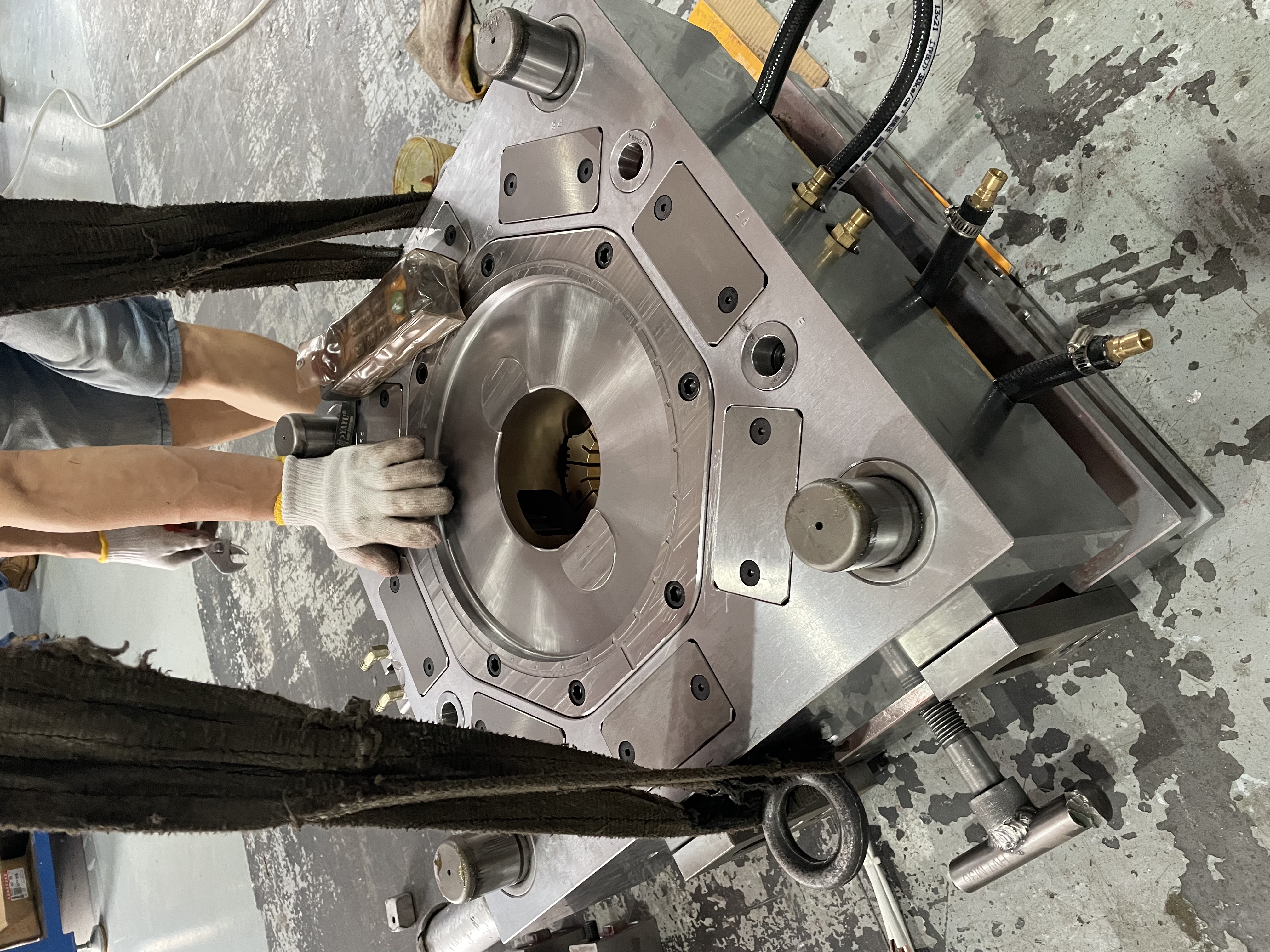

Daily operations resonate with the roar of machinery – a testament to our team’s dedication and hard work. Witnessing raw materials transform into finished products fills us with immense pride and satisfaction!

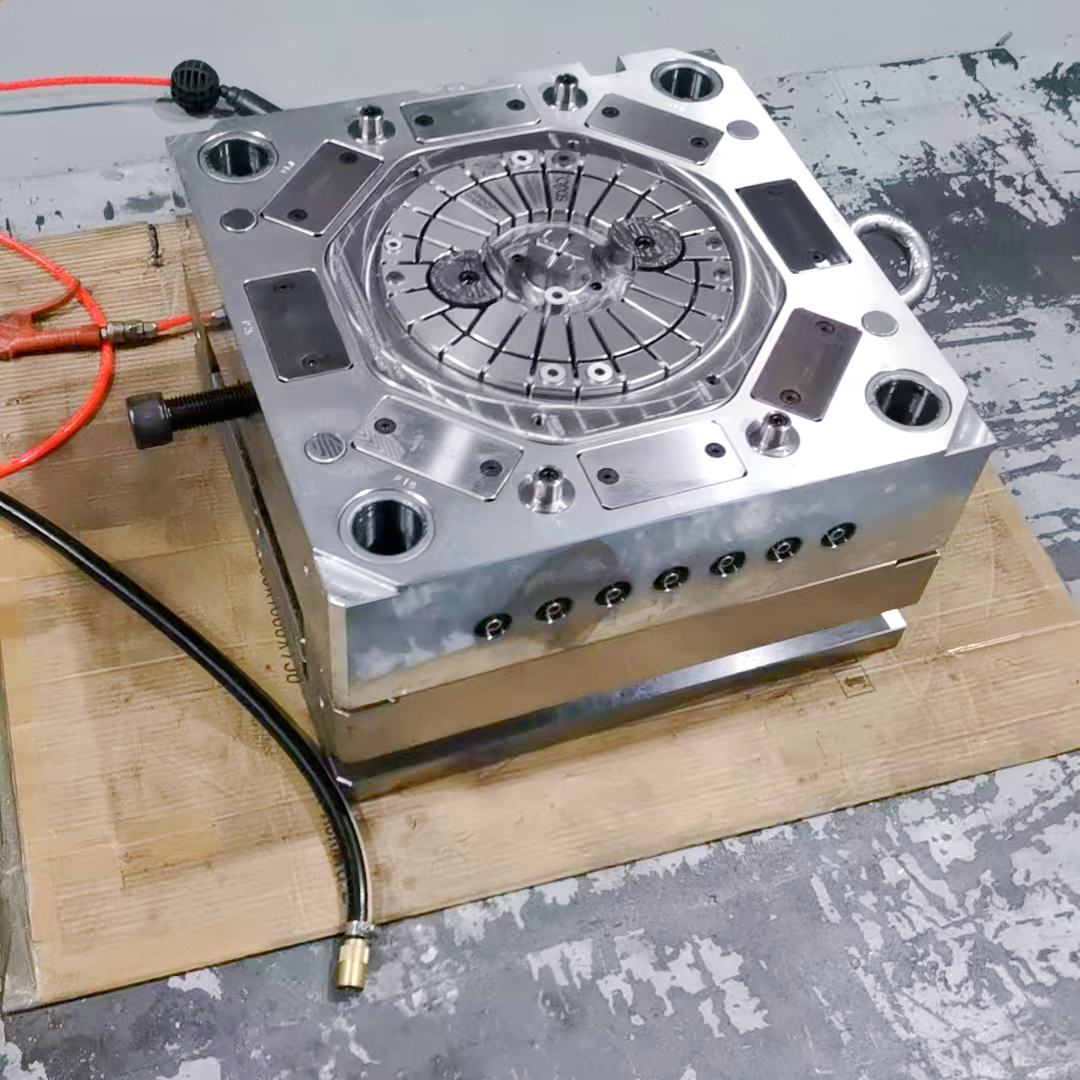

As industrial and consumer plastic products increasingly prioritize quality and diversification, manufacturers must focus on enhancing mold quality. The mold directly determines product excellence, driving the critical need for precision plastic injection mold polishing.

Mold polishing is a vital process that significantly improves surface finish, resulting in smoother, more aesthetically pleasing products. Beyond aesthetics, it boosts production efficiency and quality: inadequate mold smoothness causes products to stick during demolding, reducing both output and consistency.

The polishing process employs specialized tools (oilstones, sandpaper, polishing paste) to refine the mold cavity’s surface into a flawless mirror finish. Techniques vary based on mold material, geometry, and initial surface conditions.

From design to finished product, every step is meticulously refined to deliver superior quality. Our team leverages advanced technology and rigorous quality control, ensuring every item meets the highest standards.