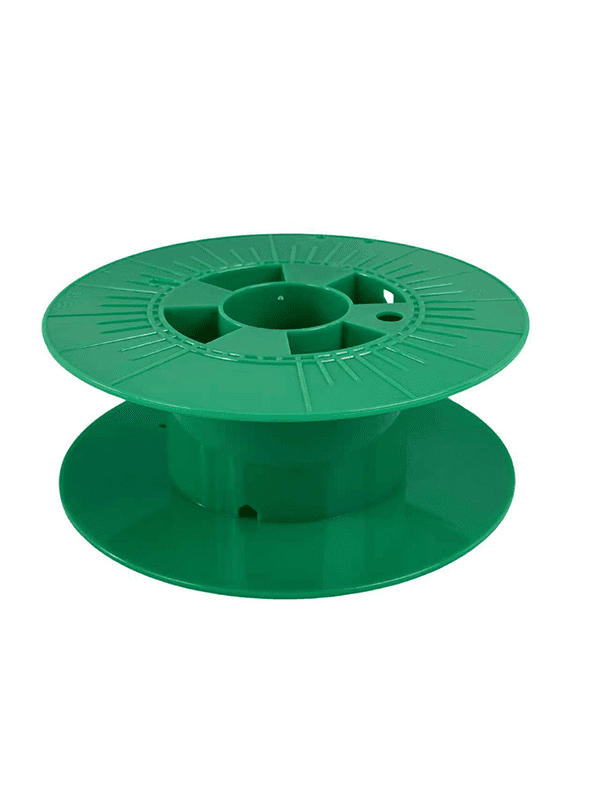

Our custom injection mold delivers high-precision, high-yield production of 3D-printing filament spools. Backed by decades of mold-making expertise, we design and manufacture single-cavity, cold-runner molds to your exact size, material, and functional specifications—ensuring consistent spool quality and rapid turnaround for your filament business.

Key Features

• Injection Mold Manufacturer Excellence

– Over 30 years of experience in cable and wire-spool tooling.

– Full-service design, prototyping, and series production under one roof.

• Mold Standard & Steel

– Built to LKM standards using 1.2344 tool steel for superior wear resistance.

– Polished cavities for mirror finishes and smooth demolding.

• High Durability & Life

– Single-cavity mold life exceeds 1,000,000 shots.

– Robust cold-runner system minimizes material waste and cycle time.

• Rapid Cycle & High Tonnage

– 40-second cycle time at 300-ton press capability.

– Stable shot-to-shot repeatability for precision spool diameter and wall thickness.

• Material & Customization

– Molded in polypropylene (PP) with custom spool geometries (inner/outer diameter, flange width).

– Optional identification ribs or logo embossing integrated into cavity design.

Parameter | Specification

Mold Standard | LKM

Mold Steel | 1.2344 (HRC 48–52)

Cavity Quantity | 1-cavity, cold runner

Product Material | Polypropylene (PP)

Mold Surface Finish | Mirror-polished

Mold Life | ≥1,000,000 shots

Cycle Time | ~40 sec

Press Tonnage | 300 ton

Lead Time | 4 weeks from drawing approval

Applications

• 3D-Printing Filament Spools – PLA, ABS, PETG, TPU, specialty composites

• Cable & Wire Spools – Data cables, audio/video wire, braided cord

• Custom Spool Solutions – Medical tubing reels, textile bobbins

Why Choose Our Injection Mold?

• Plastic Injection Mold Expertise – Precise tool manufacturing and maintenance for long mold life.

• Custom Injection Mold Service – Tailored cavity geometry, runner design, and finish options.

• End-to-End Support – From moldflow analysis and prototyping to mass production and after-sales service.

• Cost-Efficient Production – Cold-runner system and optimized cycle times reduce per-part costs.

Ordering & Contact

Ready to develop your custom filament spool mold? Contact our mold specialists:

Robert Gao

Email: robertgao@highwingmold.com

Lead Time: 4 weeks after design sign-off

We’ll guide you through design review, DFM analysis, sample approval, and on-time delivery. Rely on us as your trusted injection mold manufacturer for premium plastic injec