12-09/2024

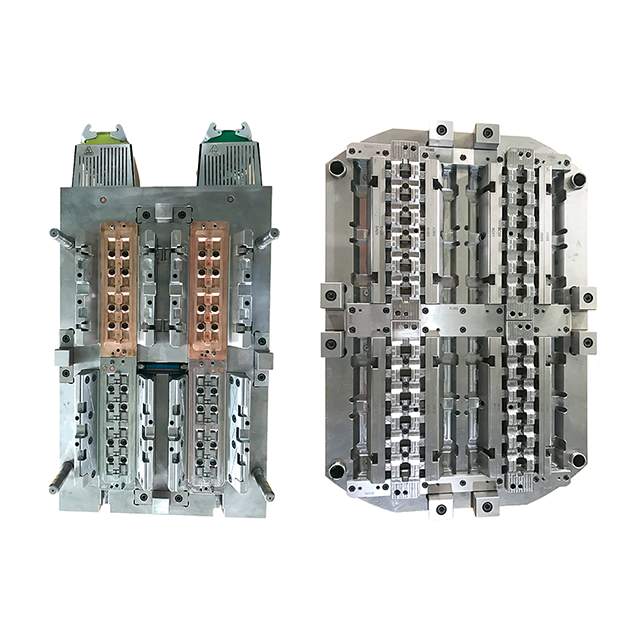

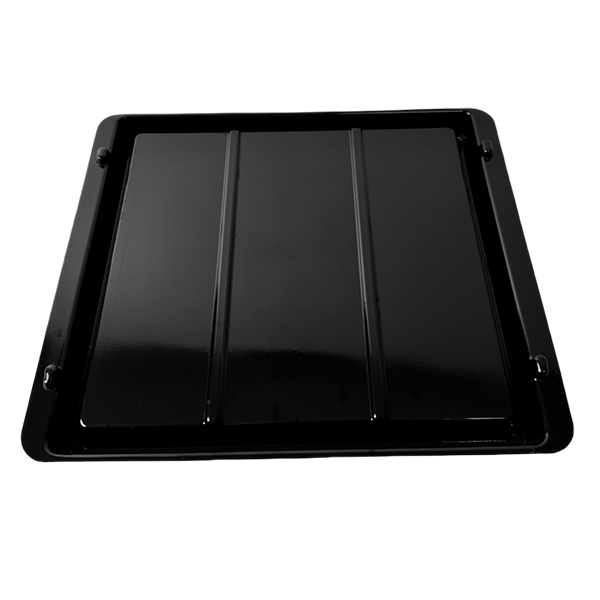

The automotive industry is experiencing a boom in technological advancements, with dash cams leading the charge in enhancing driver safety and providing crucial evidence in case of accidents. These compact devices rely on robust and durable casings to protect their sensitive internal components from the harsh conditions of daily driving. Behind the sleek exterior of every dash cam lies a crucial element: the casing mold. The manufacturers of these molds play a vital role in the production process, ensuring the quality, precision, and cost-effectiveness of dash cam production. This exploration delves into the world of top dash cam casing molds manufacturers, examining the factors that contribute to their success and the impact they have on the wider automotive technology market.