05-08/2025

Automotive Interior Restoration: OEM Custom Solutions Through Advanced Injection Molding

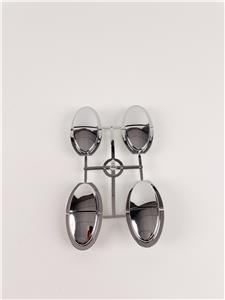

For drivers seeking factory-fresh interiors, OEM custom dashboard solutions offer the perfect balance of authenticity and affordability. These plastic molded parts, manufactured using precision injection molding techniques, replicate original designs while providing customization options through adaptor fascia panels and other plastic car interior dashboard accessories.