12-05/2024

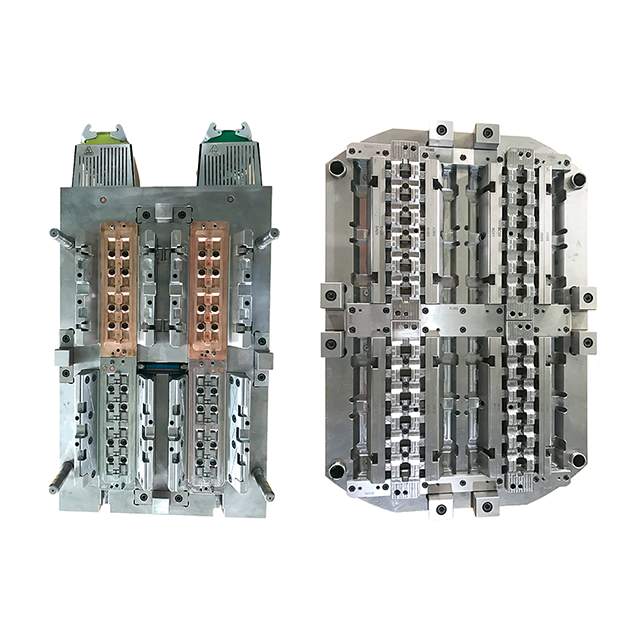

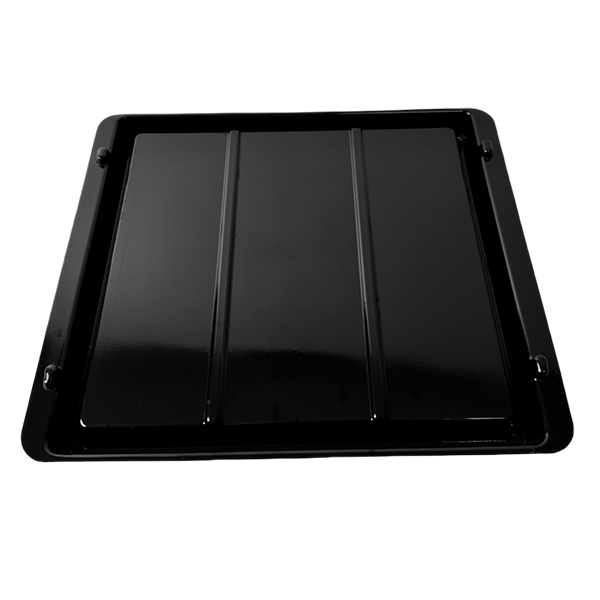

Reliable Injection Molds Gutter Systems represent a significant advancement in the design and manufacturing of gutter systems for residential and commercial properties. Traditional gutter systems, often made of galvanized steel or aluminum, are susceptible to rust, corrosion, and dents, requiring frequent repairs and replacements. Reliable Injection Molds addresses these issues by utilizing high-quality, durable materials and precision injection molding techniques to create superior gutter systems that boast increased longevity, aesthetic appeal, and enhanced performance. This innovative approach revolutionizes the industry, offering a long-term solution for effective water management and property protection.